Advantages of water knife cutting stainless steel

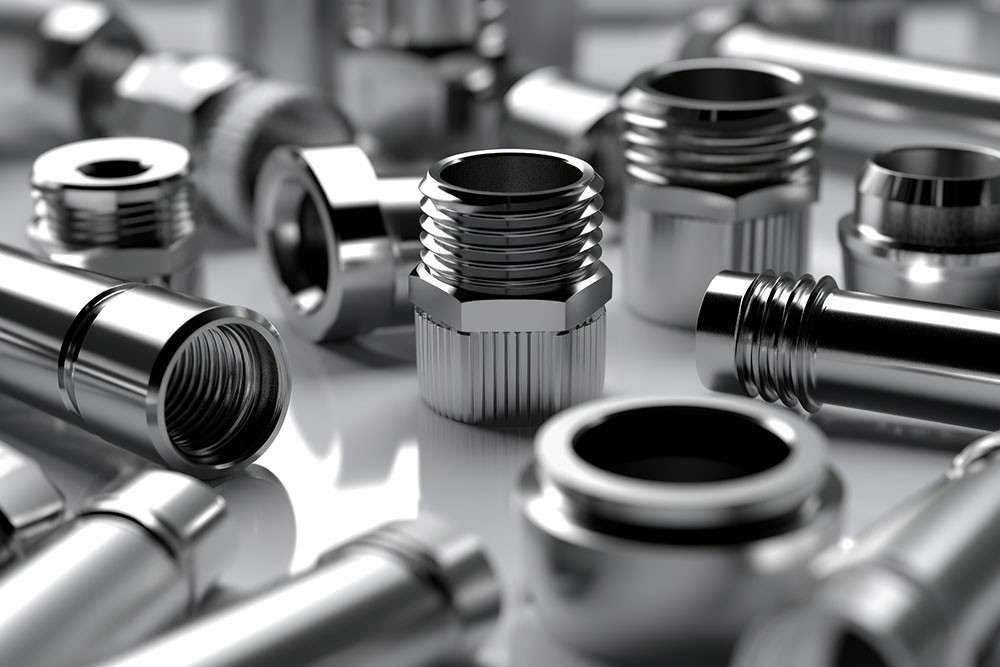

As a commonly used industrial material, stainless steel is widely used in manufacturing industry. Stainless steel has the advantages of high strength and corrosion resistance, so it is widely used in the manufacture of ships, chemical equipment, refrigeration and air conditioning equipment, building decoration and other fields

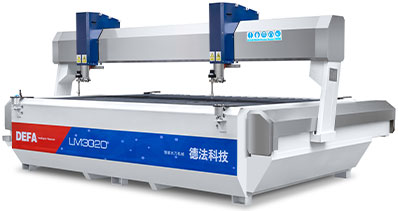

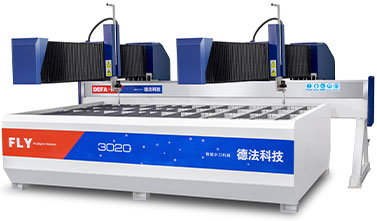

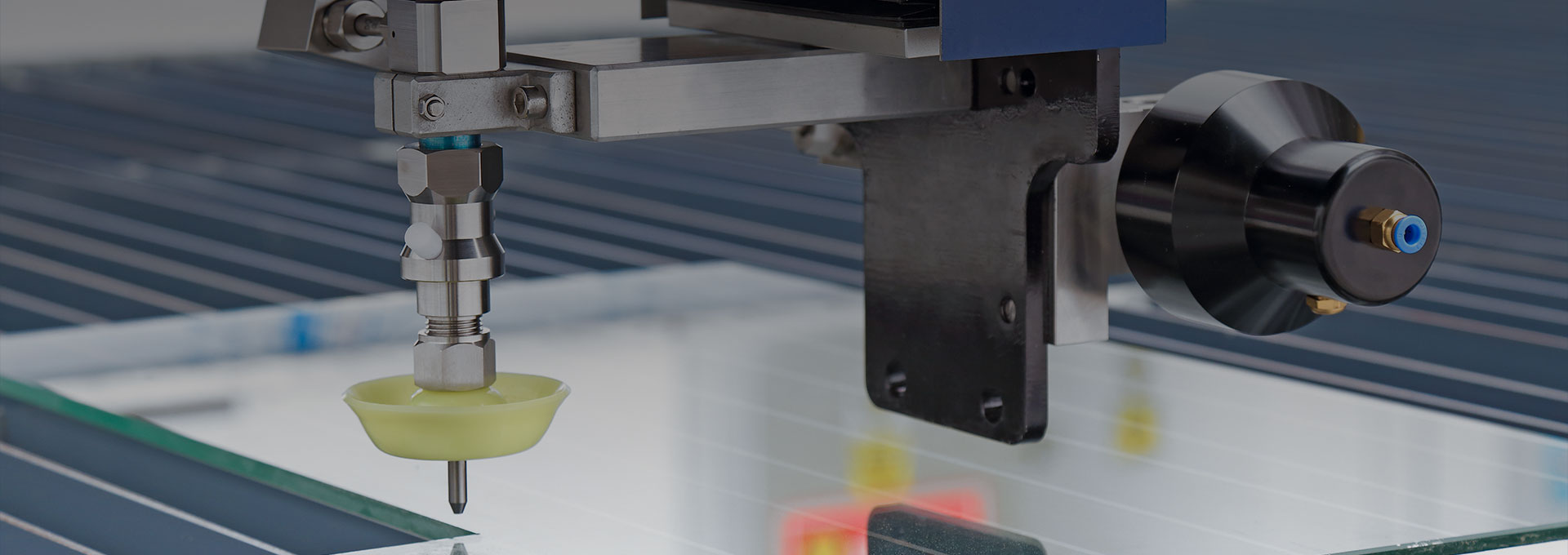

Water knife cutting high pressure water jet cutting technology, is a use of high pressure water cutting machine. Under the control of the computer, the workpiece can be arbitrarily carved, and the texture of the material is little affected. Because of its low cost, easy operation, and high yield, water cutting is gradually becoming the mainstream cutting method in industrial cutting technology.

1, strong versatility, almost all materials can be cut;

2, water knife cold cutting, not easy to deformation, no burning, does not change the physical and chemical properties of the material;

3, small slit, 2mm-2.7mm (according to the thickness of the material);

4, clean and environmental protection;

5. The cutting surface is relatively neat and smooth.

水刀切割设备参数

1.High efficiency: water knife cutting speed is fast, can greatly shorten the manufacturing cycle;

2. Precision: water knife cutting precision is high, can perfectly achieve a variety of complex shape cutting;

3. No damage: water knife cutting does not need to heat the material, will not produce thermal cracks and residual stress, will not cause any damage to the surface of the material and internal structure;

4. Energy saving and environmental protection: Water knife cutting does not need to use chemicals and toxic gases, is an energy saving, environmental protection, safe and healthy cutting method.